Development of a user-friendly cost-optimizing planning tool for nuclear dismantling projects taking into account material flows for resource planning (NukPlaRStoR)

- contact:

-

project group : - funding:

Federal Ministry of Education and Research

Funding code 15S9414A

- partner:

- start:

06/2019

- end:

12/2022

News

"Project planning with added value" – this is the title of a current report in the KIT blog RESEARCH TO BUSINESS about the project planning tool developed by IIP and RODIAS GmbH. The planning tool, brought to market as software product OPTIRA, was developed within the BMBF-funded research projects MogaMaR and NukPlaRStoR. The development was supported by VPC Nukleare Dienstleistungen GmbH with know-how from nuclear dismantling. (October 01, 2021)

In June 2021, the model for optimized project planning developed in the NukPlaRStoR project was awarded the 3rd prize at the KIT NEULAND innovation competition in the category Transfer Prize. The innovation competition takes place annually and offers KIT scientific employees the opportunity to present their innovative ideas and projects to a company jury, which then evaluates them. More information about the award ceremony can be found here. (July 21, 2021)

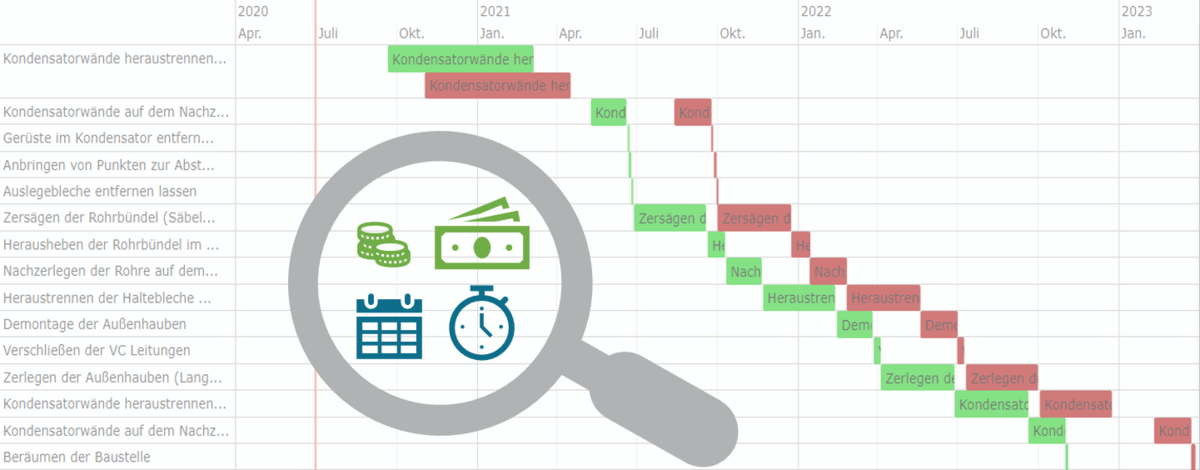

The models and methods for optimizing project planning developed within the projects "Model development of a holistic project management system for nuclear dismantling projects (MogaMaR)" and NukPlaRStoR at the IIP are offered by our project partner RODIAS GmbH as software product OPTIRA since mid 2020. OPTIRA is an innovative add-on to conventional project planning tools that enables the automated optimization of especially large and complex projects of any kind. The models and methods developed at the IIP are integrated as an independent program library and carry out the mathematical optimization. On the part of RODIAS, extensive user and application interfaces, program control as well as data management and visualization were added on the way to the now available final product. In the further course of the NukPlaRStoR project, additional functionalities will be developed in cooperation with the project partners and supplemented in OPTIRA, especially in connection with material flow planning in nuclear decommissioning projects. (February 26, 2021)

Description

Estimates by international organisations (e.g. the International Energy Agency [1] or the European Commission [2]) show that the dismantling of nuclear plants is becoming a national and international focus of the energy and dismantling industries. A strongly developing international market can be expected in the coming decades (cf. for example [3]). Due to the low experience gained so far in nuclear dismantling, the European Commission sees this knowledge and market gap as a great opportunity for states of the European Union to become global pioneers in this field [4].

Already completed and still ongoing dismantling projects of nuclear plants show that dismantling is technically safe. However, the operators of nuclear facilities as well as responsible dismantling companies point out that there is still considerable potential for optimisation and cost savings in the project management of the dismantling of nuclear facilities in comparison to technology. This is particularly evident with regard to the extreme time and cost deviations from the original planning of some current nuclear decommissioning projects. A major reason for these deviations is that the planning of nuclear dismantling projects represents a major challenge due to low empirical values and the large scope (many dismantling steps, many actors involved, long project duration, complex permits, complex material and waste flows, etc.). Currently existing project planning tools do not completely cover the requirements of nuclear dismantling projects.

Aims

The aim of the NukPlaRStoR joint project is to develop a planning tool that is specifically tailored to the needs of nuclear dismantling projects. All essential requirements for nuclear dismantling planning are to be considered and an optimising planning approach is to be developed with the help of mathematical methods and implemented as a planning tool. The planning of nuclear dismantling projects is thus considerably simplified. The planning tool to be developed should enable the calculation of an optimal plan (with regard to costs and in compliance with safety regulations) containing all tasks to be performed as well as all material flows occurring during the decommissioning. Based on the material flows, the planning tool should enable logistical planning (e.g. transport and processing within the plant, incl. conditioning) as well as container planning incl. final disposal documentation. Furthermore, the planning tool should be fully applicable for the planning of nuclear dismantling projects and can be interfaced with other programs (e.g. for the visualisation of the calculated plan or for residual material tracking). An essential part of the work in the joint project is that the planning tool is user-friendly, so that it can be used without much previous knowledge.

[1] International Energy Agency (2014): World Energy Outlook 2014.

[2] European Commission (2016): Communication from the commission: Nuclear Illustrative Programme.

[3] Volk, R. et al. (2019): The future of nuclear decommissioning - A worldwide market potential study.

[4] European Commission (2016): Communication from the commission: Nuclear Illustrative Programme presented under Article 40 of the Euratom Treaty for the opinion of the European Economic and Social Committee.